Flexible graphene electrodes embedded in textiles

May 12, 2015

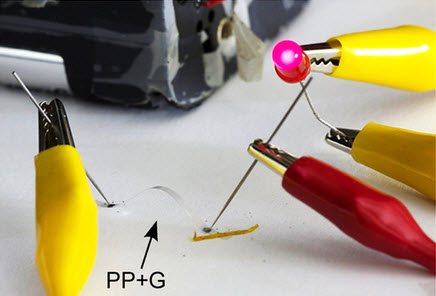

Photograph of an electric circuit with a LED light, closed with a bent and suspended transparent PP fiber coated with graphene. The visible graphite contacts were only used to show the channel length. (credit: A. I. S. Neves et al./Scientific Reports)

An international team of scientists has developed a new technique to embed transparent, flexible graphene electrodes into fibers commonly used in textiles. The technology makes it possible to create wearable electronic devices, such as clothing containing smartphones and devices for biomedical monitoring and personal security.

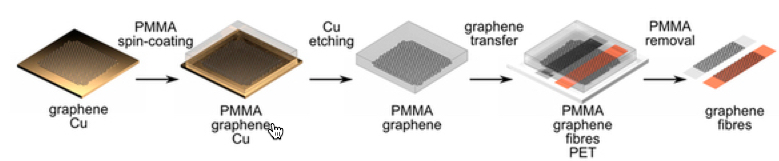

General graphene transfer steps: CVD growth on copper; PMMA coating; copper etching; graphene transfer to the fibers and PMMA removal (credit: A.I.S Neves et al./Scientific Reports)

The monolayer graphene was grown by chemical vapor deposition (CVD) on copper foil and applied to fibers commonly used by the textile industry, using wet transfer of monolayer graphene to polypropylene and polylactic acid biobased fibers.

The international collaborative research, which includes experts from the Centre for Graphene Science at the University of Exeter, the Institute for Systems Engineering and Computers, Microsystems and Nanotechnology (INESC-MN) in Lisbon, the Universities of Lisbon and Aveiro in Portugal and the Belgian Textile Research Centre (CenTexBel), is described in an open-access paper published in the leading scientific journal Scientific Reports.

The research was supported by the UK’s Engineering and Physical Sciences Research Council (EPSRC) and by the Royal Society.

Abstract of Transparent conductive graphene textile fibers

Transparent and flexible electrodes are widely used on a variety of substrates such as plastics and glass. Yet, to date, transparent electrodes on a textile substrate have not been explored. The exceptional electrical, mechanical and optical properties of monolayer graphene make it highly attractive as a transparent electrode for applications in wearable electronics. Here, we report the transfer of monolayer graphene, grown by chemical vapor deposition on copper foil, to fibers commonly used by the textile industry. The graphene-coated fibers have a sheet resistance as low as ~1 kΩ per square, an equivalent value to the one obtained by the same transfer process onto a Si substrate, with a reduction of only 2.3 per cent in optical transparency while keeping high stability under mechanical stress. With this approach, we successfully achieved the first example of a textile electrode, flexible and truly embedded in a yarn.