Hot-fire tests show 3D-printed rocket parts rival traditionally manufactured parts

July 25, 2013

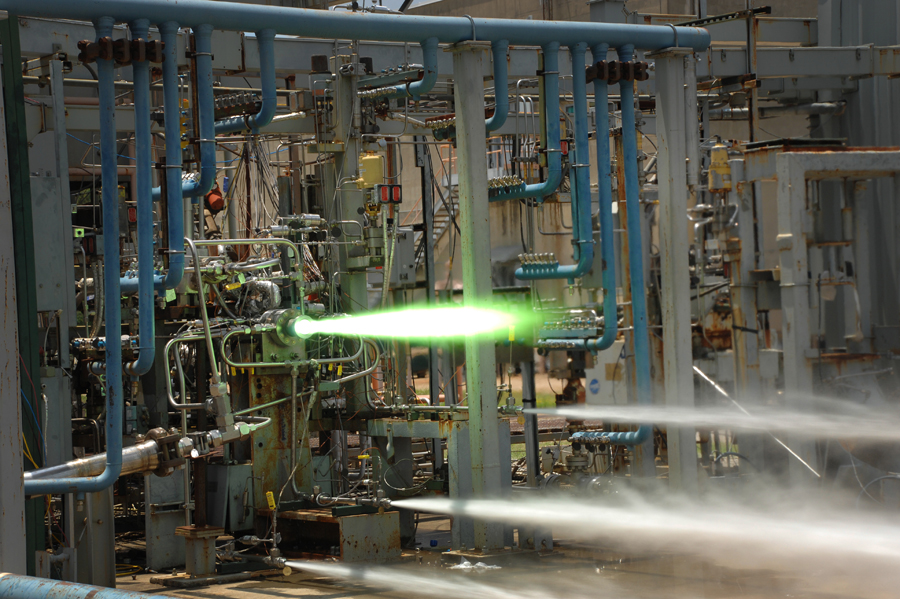

Marshall engineers installed the injector in a subscale RS-25 engine model. During hot-fire testing, the engine and part were exposed to temperatures of nearly 6,000 degrees Fahrenheit. (Credit: NASA/MSFC)

NASA engineers at the Marshall Space Flight Center in Huntsville, Ala., have put rocket engine parts to the test and compared their performance to parts made the old-fashioned way with welds and multiple parts during planned subscale acoustic tests for the Space Launch System (SLS) heavy-lift rocket.

In little more than a month, Marshall engineers built two subscale injectors with a specialized 3-D printing machine and completed 11 mainstage hot-fire tests, accumulating 46 seconds of total firing time at temperatures nearing 6,000 degrees Fahrenheit while burning liquid oxygen and gaseous hydrogen.

“We saw no difference in performance of the 3-D printed injectors compared to the traditionally manufactured injectors,” said Sandra Elam Greene, the propulsion engineer who oversaw the tests and inspected the components afterward. “Two separate 3-D printed injectors operated beautifully during all hot-fire tests.”

Post-test inspections showed the injectors remained in such excellent condition and performed so well the team will continue to put them directly in the line of fire.

“The additive manufacturing process has the potential to reduce the time and cost associated with making complex parts by an order of magnitude,” said Chris Singer, director of the Marshall Center’s Engineering Directorate.

Traditional subscale rocket injectors for early SLS acoustic tests took six months to fabricate, had four parts, five welds and detailed machining and cost more than $10,000 each. Marshall materials engineers built the same injector in one piece by sintering Inconel steel powder with a state-of-the-art 3-D printer. After minimal machining and inspection with computer scanning, it took just three weeks for the part to reach the test stand and cost less than $5,000 to manufacture.

Since additive manufacturing machines have has become more affordable, varied, and sophisticated, this materials process now offers many possibilities for making every phase of NASA missions more affordable.

The SLS injector test series complements a series of liquid oxygen and gaseous hydrogen rocket assembly firings at NASA’s Glenn Research Center in Cleveland, which hot-fire tested an additively manufactured, select laser melted injector developed through collaboration of industry and government agencies.

A J-2X engine exhaust port cover made at the Marshall Center became the first 3-D printed part tested during a full-scale engine hot-fire test at NASA’s Stennis Center.

Marshall materials engineers are currently making a baffle critical for pogo vibration mitigation; it will be tested at Marshall and Stennis and is a potential candidate for the first SLS mission in 2017. Marshall engineers are finishing up ground tests with Made in Space, a Moffett Field, California company working with NASA to develop and test a 3-D printer that will build tools on the International Space Station next year. NASA’s Johnson Space Center in Houston is even exploring printing food in space.

“At NASA, we recognize ground-based and in-space additive manufacturing offer the potential for new mission opportunities, whether printing rocket parts, tools or entire spacecraft,” Singer said. “Additive manufacturing will improve affordability from design and development to flight and operations, enabling every aspect of sustainable long-term human space exploration.”

NASA is a leading partner in the National Network for Manufacturing Innovation and the Advanced Manufacturing Initiative, which explores using additive manufacturing and other advanced materials processes to reduce the cost of spaceflight.