Lower-cost high-brightness LEDs possible with ‘wonder material’ perovskite

August 11, 2014

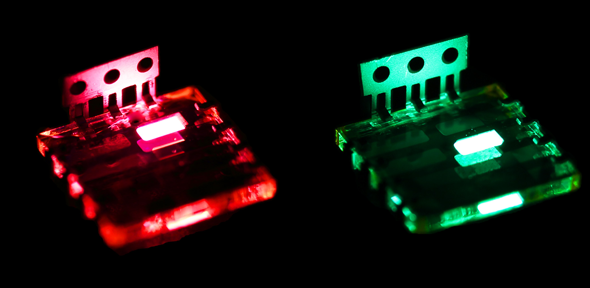

LEDs made from perovskite (credit: Zhi-Kuang Tan)

Researchers from the University of Cambridge, University of Oxford, and Ludwig-Maximilians-Universität in Munich have demonstrated a new hybrid form of perovskite* materials, using them to make high-brightness LEDs that the researchers say will be cheaper and easier to manufacture in the future.

The materials could also be used in flexible color displays.

The results are published in the journal Nature Nanotechnology.

“These organometal halide perovskites are remarkable semiconductors,” said Zhi-Kuang Tan, a PhD student at the University of Cambridge’s Cavendish Laboratory and the paper’s lead author. “We have designed the diode structure to confine electrical charges into a very thin layer of the perovskite, which sets up conditions for the electron-hole capture process to produce light emission.”

The perovskite LEDs are made using a simple scalable process in which a perovskite solution is prepared and spin-coated onto the substrate. The process does not require high temperature heating steps, a high vacuum, and complex purification procedures, so LEDs will be cheap to manufacture on a large scale, according to Tan.

The team is now looking to increase the efficiency of the LEDs and to use them for diode lasers, which are used in a range of scientific, medical and industrial applications, such as materials processing and medical equipment.

The first commercially-available LEDs based on perovskite could be available within five years, the researchers say.

Abstract of Nature Nanotechnology paper

Solid-state light-emitting devices based on direct-bandgap semiconductors have, over the past two decades, been utilized as energy-efficient sources of lighting. However, fabrication of these devices typically relies on expensive high-temperature and high-vacuum processes, rendering them uneconomical for use in large-area displays. Here, we report high-brightness light-emitting diodes based on solution-processed organometal halide perovskites. We demonstrate electroluminescence in the near-infrared, green and red by tuning the halide compositions in the perovskite. In our infrared device, a thin 15 nm layer of CH3NH3PbI3–xClx perovskite emitter is sandwiched between larger-bandgap titanium dioxide (TiO2) and poly(9,9′-dioctylfluorene) (F8) layers, effectively confining electrons and holes in the perovskite layer for radiative recombination. We report an infrared radiance of 13.2 W sr−1 m−2 at a current density of 363 mA cm−2, with highest external and internal quantum efficiencies of 0.76% and 3.4%, respectively. In our green light-emitting device with an ITO/PEDOT:PSS/CH3NH3PbBr3/F8/Ca/Ag structure, we achieved a luminance of 364 cd m−2 at a current density of 123 mA cm−2, giving external and internal quantum efficiencies of 0.1% and 0.4%, respectively. We show, using photoluminescence studies, that radiative bimolecular recombination is dominant at higher excitation densities. Hence, the quantum efficiencies of the perovskite light-emitting diodes increase at higher current densities. This demonstration of effective perovskite electroluminescence offers scope for developing this unique class of materials into efficient and colour-tunable light emitters for low-cost display, lighting and optical communication applications.

“Perovskite” is a general term used to describe a group of materials that have a distinctive crystal structure of cuboid and diamond shapes. Their efficiency at converting light into electrical energy has opened up a wide range of potential applications. The perovskites that were used to make the LEDs are known as organometal halide perovskites, and contain a mixture of lead, carbon-based ions, and halogen ions known as halides. These materials dissolve well in common solvents, and assemble to form perovskite crystals when dried, making them cheap and simple to make.