Ten ways 3D printing could change space

April 16, 2014

The European Space Agency (ESA) is investigating the potential of additive manufacturing (AM), or 3D printing, to transform how space missions are put together, and has identified ten ways.

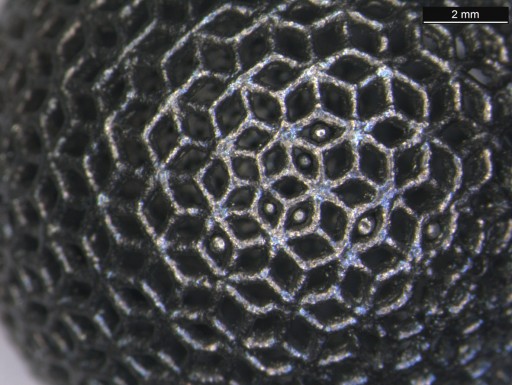

1. Items impossible to make any other way

This titanium-lattice ball is a good example of additive manufacturing capabilities. These hollow balls have a complex external geometry, making them incredibly light while remaining stiff and opening up possibilities for future space applications. They could not have been manufactured as a single part using a conventional manufacturing process.

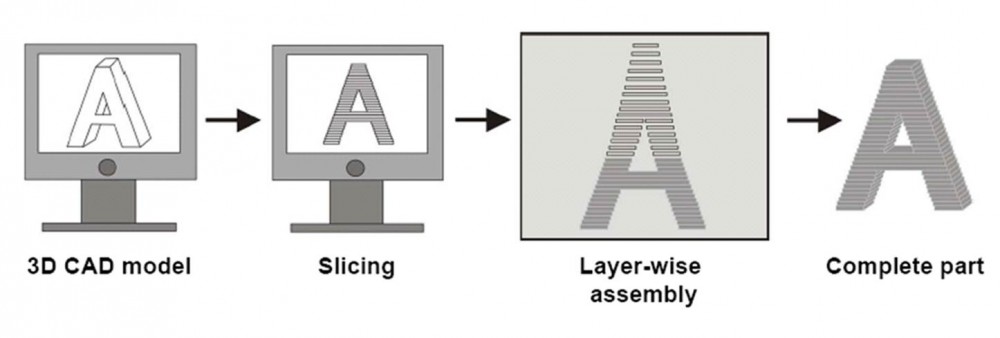

2. Computer designs translated to physical models

Instead of standard “subtractive manufacturing” — where material is cut away from a single piece — additive manufacturing involves building up a part from a series of layers, each one printed on top of the other.

The process starts with a computer-aided design (CAD) model, which is then sliced horizontally apart to plan its layer-based physical construction. Anything suitable for the printing process can be designed by computer then printed as an actual item, typically by melting powder or wire materials, in plastic or metal.

3. Novel design rules

3D-printed bracket for antenna support. As a test case ESA redesigned it from its space-flown equivalent using topographic optimization, achieving 46% mass saving and undergoing successful vibration testing. (Credit: ESA)

“AM offers a totally different way of designing,” explains Laurent Pambaguian of ESA’s Materials Technology Section, coordinating the Agency’s AM research. “Traditional design rules are often linked to giving a cutting tool access to the bulk part — how do we remove the surplus material to produce the final item?

“AM, on the other hand, doesn’t mean we do away with all restrictions, but we are moving away for the traditional ‘design for manufacturing’ approach towards ‘design for need’.

“We also require fewer manufacturing steps, less material and energy — making it a greener process as well. The real challenge is to grasp the new AM design rules, and change our standard way of thinking accordingly, in order to maximize the benefits AM can bring us.”

4. Benefiting space, a low-volume industry

A pair of 3D-printed replicas of the glove worn by ESA astronaut Hans Schlegel while spacewalking, one life-size and one at one-tenth scale. These models were produced using fused deposition modeling of thermoplastic by ESA’s Mechanical Workshop based at ESTEC in Noordwijk, the Netherlands. (Credit: ESA)

Laurent believes that AM, if applied well, can overcome many problems manufacturing for space has traditionally faced: “Space is a low-volume industrial sector, we need a relatively small amount of parts, but very well made. So, for instance, we might require only several kilos of a particular material, but then find it is only available to be purchased in 10-ton bulks.

“Or there are certain processes that are effectively out of reach: take metallic injection molding, which produces very good quality parts, but you might need to manufacture at least 100,000 to pay for the cost of the mold. So with AM we have the hope of replacing other technologies that are not affordable for us.”

5. Making models

Down on the ground, ESA engineers already make routine use of AM in various ways. Take the team at the Concurrent Design Facility, who use networked computer tools and multimedia tools for the rapid design of future space missions. They also have a plastic 3D printer at their disposal. As a virtual spacecraft takes shape on the screens before them, the team can also pass around a scale model of the same design, made out of the same plastic as Lego bricks.And metallic 3D-printed parts commissioned from outside firms have also been used to refit or repair full-scale equipment in the ESTEC Test Centre, Europe’s leading collection of spaceflight simulation facilities under a single roof.

6. 3D-printed test items

Original and 3D-printed version of the water on-off valve (Woov) flown aboard ESA’s Columbus module attached to ISS. Originally made in stainless steel with a single weld and thin walls, the Additive Manufacturing demonstration version was instead manufactured in titanium with a 40% mass reduction. (Credit: ESA)

But before AM parts can be employed on actual space missions, ESA’s materials engineers need to be confident that they can achieve the exacting quality levels needed. Back in 2009, when the Agency began this research, its starting point was to use AM to reproduce items that had actually flown in space.

“The very first item we produced was a titanium copy of a stainless steel ‘woov’ (water on-off valve),” explains Laurent. “This has been flown on ESA’s Columbus Space Station module, as part of its plumbing.

“We choose the woov because it contains both thick and thin walls, as well as a weld. With our AM version we were able to remove the weld — an unwanted point of weakness — reproduce the part in titanium at an affordable cost and, through changing the material, reduce the item mass by 40%.”

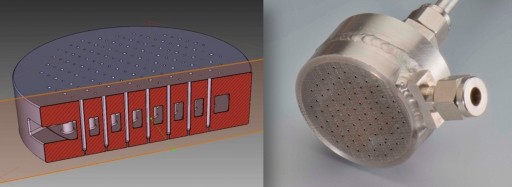

7. RF filters and engine parts

3D-printed with selective laser melting, this Additive Manufactured version of the injector showerhead used inside combustion chambers manages to reproduce a complex internal geometry, subsequently passing a pressurised leak test. The standard version requires more than a hundred separate welds to produce, done without in this AM-version. The main remaining challenge has been to produce holes of the correct size required, currently requiring secondary processing to achieve. (Credit: ESA)

Follow-up test items included an antenna support strut, where mass was reduced by 46% and a radio-frequency filter with an internal silver coating — normally produced by bolting halves together — had its mass reduced by 50% and its manufacturing time slashed by several weeks.

Its internal geometry was also made more wavy: the silver coating required to optimize its radio-frequency performance is far easier to apply than when dealing with sharp corners encountered in today’s state-of-the-art hardware. Such tailored design is another advantage of AM.

ESA’s Propulsion Engineering section also took an early interest in AM, as a way of building the extremely complex shapes required by rocket nozzles and combustion chambers. “We began by remaking a showerhead injector, with complex internal geometry and more than a hundred separate welds,” explains Matthew Smith.

“The biggest challenge for the selective laser melting metal AM technology we used was achieving the 150 micron-diameter holes studding the 25 mm-diameter showerhead, but we’re currently talking to suppliers that report capability to achieve this.”

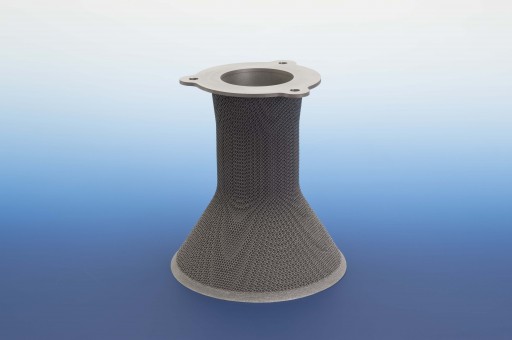

8. Lightweight lattices

3D-printed engine nozzle incorporating a lattice structure, reducing its mass and production cost while also improving its thermal performance, thanks to a greatly increased surface area (credit: ESA)

The same kind of honeycombed lattices demonstrated by the titanium balls offer a way of reducing the mass and cost of rocket chambers and nozzles. The lattices can also improve thermal resilience, considering that engine temperatures can rise as high as 2500°C. Such lattices have a hugely increased surface area compared to standard solid items, enabling increased radiative cooling.Similar AM-printed lattices are also being considered as more durable thruster catalyst beds, which will escape the typical degradation in performance of standard pellet-based catalysts over a propulsion system’s lifetime.Carefully tailored AM lattices have also been investigated for “propellant management devices” — sponge-like elements inside a propulsion tank that help prevent bubbles and ensure steady thruster performance.

The broader potential of lattices to slash the mass of future satellite structure is also being considered.

9. Steps on the way to space

We’re still a long-way from the routine use of AM parts in space. Problems like material post-processing, surface coating and ensuring the necessary precision geometries still need to be solved. And new qualification standards have to be written — but progress is being made.

Occasional AM parts have already made it up to orbit: a 3D-printed plastic toolbox was flown up to Columbus last year. NASA has announced plans to fly a plastic 3D-printing machine to the Station.

Meanwhile, ESA and the European Commission have embarked on a project to perfect the printing of space-quality metal components. The AMAZE project — Additive Manufacturing Aiming Towards Zero Waste & Efficient Production of High-Tech Metal Products — involves 28 industrial partners across Europe.

10. Future potential

Concept for a multi-dome lunar base under construction, using 3D printing. Once assembled, the inflated domes are covered with a layer of 3D-printed lunar regolith by robots to help protect the occupants against space radiation and micrometeoroids. (Credit: ESA)

How might AM transform space missions in future? An ESA project to design a lunar base using 3D-printed local lunar rock demonstrates the broad span of its potential.

Manned missions could carry a 3D printer with them to ensure full self-reliance as they fly many months or years distant from Earth. Any broken item could be quickly and easily replaced. This approach has already been validated by ESA by manufacturing and functionally testing parts that have required fixing during past manned missions, including screws, clamps and even plastic gloves.

Or satellites in space could self-print new subsystems to provide new capabilities, in the same manner that today’s space probes are still having their software written on the way to their destination.

Down on the ground, the possibilities are just as exciting: slashing the energy and mass needed for manufacturing could shrink the environmental footprint of the space industry hugely, the reason why AM is also of interest to ESA’s Clean Space initiative, which is tasked with reducing the space industry’s impacts on the environment.