3-D-printed robot is hard inside, soft outside, and capable of jumping without hurting itself

July 10, 2015

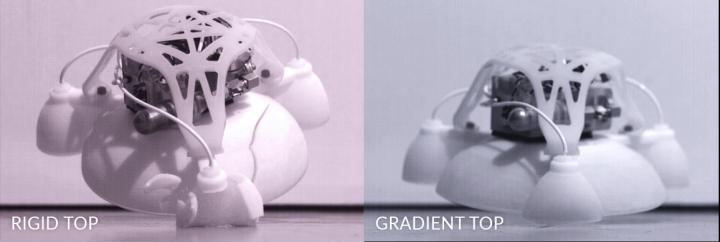

Left: the rigid top fractures on landing, while the top made of nine layers going from rigid to flexible remains intact (credit: Jacobs School of Engineering/UC San Diego, Harvard University)

Engineers at Harvard University and the University of California, San Diego, have created the first robot with a 3D-printed body that transitions from a rigid core to a soft exterior. The robot is capable of more than 30 untethered jumps at a time and is powered by a mix of butane and oxygen.

The researchers describe the robot’s design, manufacturing and testing in the July 10 issue of the journal Science. Michael Tolley, an assistant professor of mechanical engineering at UC San Diego, and one of the paper’s co-lead authors, believes bringing together soft and rigid materials will help create a “new generation of fast, agile robots that are more robust and adaptable than their predecessors and can safely work side by side with humans.” And maybe help prevent (or cushion) those “that’s gotta hurt” falls experienced by some robots participating in the recent DARPA Robotics Challenge.

The idea of blending soft and hard materials into the robot’s body came from nature, Tolley said. For example, certain species of mussels have a foot that starts out soft and then becomes rigid at the point where it makes contact with rocks. “In nature, complexity has a very low cost,” Tolley said. “Using new manufacturing techniques like 3D printing, we’re trying to translate this to robotics.”

Soft robots tend to be slow, especially when accomplishing tasks without being tethered to power sources and other electronics, said Tolley, who recently co-authored a research review on soft robotics for Nature (Rus, Tolley, v. 521, pp. 467-475). Adding rigid components should help, without compromising the safety of the humans who would work with them.

In the case of the robot described in Science, rigid layers also make for a better interface with the device’s electronic brains and power sources. The soft layers make it less vulnerable to damage when it lands after jumping .

How it works

The robot is made of two nestled hemispheres. The top hemisphere is like a half shell, 3D-printed in once piece, with nine different layers of stiffness, creating a structure that goes from rubber-like flexibility on the exterior to full rigidity near to core. Researchers tried several versions of the design and concluded that a fully rigid top would make for higher jumps. But a more flexible top was more likely to survive impacts on landing, allowing the robot to be reused. They decided to go with the more flexible design.

The bottom half of the robot is flexible and includes a small chamber where oxygen and butane are injected before it jumps. After the gases are ignited, this half behaves very much like a basketball that gets inflated almost instantaneously, propelling the robot into a jump. When the chemical charge is exhausted, the bottom hemisphere goes back to its original shape.

The two hemispheres surround a rigid core module that houses a custom circuit board, high-voltage power source, battery, miniature air compressor, butane fuel cell and other components. In a series of tests, the robot jumped two and a half feet (0.75 m) in height and half a foot (0.15m) laterally. In experiments, the robot jumped more than 100 times and survived an additional 35 falls from a height of almost four feet.

Jacobs School of Engineering/UC San Diego, Harvard University | 3D-printed robot is hard at heart, soft on the outside

Wyss Institute/Harvard University | 3D Printed Soft Jumping Robot

Abstract of A 3D-printed, functionally graded soft robot powered by combustion

Roboticists have begun to design biologically inspired robots with soft or partially soft bodies, which have the potential to be more robust and adaptable, and safer for human interaction, than traditional rigid robots. However, key challenges in the design and manufacture of soft robots include the complex fabrication processes and the interfacing of soft and rigid components. We used multimaterial three-dimensional (3D) printing to manufacture a combustion-powered robot whose body transitions from a rigid core to a soft exterior. This stiffness gradient, spanning three orders of magnitude in modulus, enables reliable interfacing between rigid driving components (controller, battery, etc.) and the primarily soft body, and also enhances performance. Powered by the combustion of butane and oxygen, this robot is able to perform untethered jumping.