A touch-sensitive conductive plastic skin that heals itself

November 12, 2012

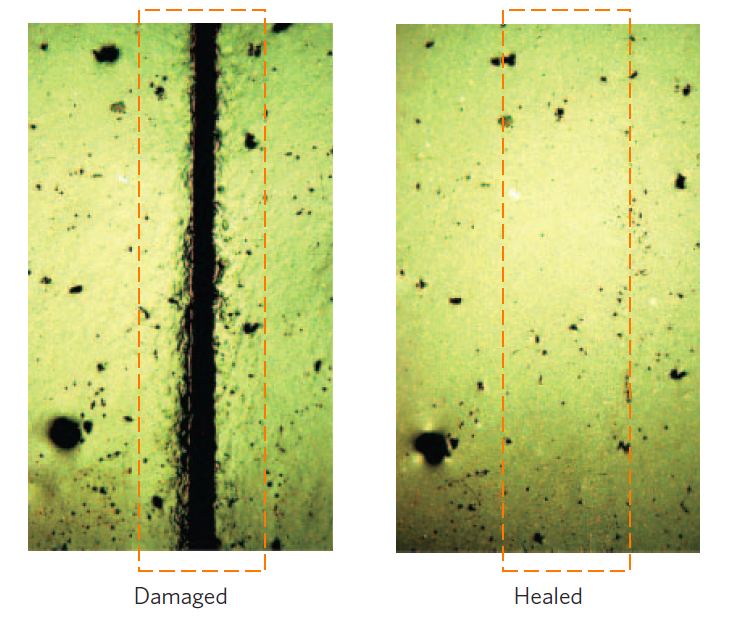

Optical microscope image of damaged sample and complete scar healing with self-healing composite (credit: Benjamin C.-K. Tee, Chao Wang, Ranulfo Allen, Zhenan Bao/Nature Nanotechnology)

The first synthetic material that is both sensitive to touch and capable of healing itself quickly and repeatedly if torn or cut at room temperature has been developed by a team of Stanford University chemists and engineers headed by Professor Zhenan Bao.

The advance could lead to smarter prosthetics, resilient personal electronics that repair themselves, and more sensitive soft robotics (such as the “Frankenoctopus“).

Not only is our skin sensitive — sending the brain precise information about pressure and temperature — but it also heals efficiently to preserve a protective barrier against the world and is conductive. The challenge was combining these features in a single synthetic material.

In the last decade, there have been major advances in synthetic skin, said Bao, but they had major drawbacks. Some had to be exposed to high temperatures, making them impractical for day-to-day use.

Others could heal at room temperature, but repairing a cut changed their mechanical or chemical structure, so they could heal themselves only once. Most important, no self-healing material was a good bulk conductor of electricity, a crucial property for use with electronic devices.

How it works

They started with a plastic consisting of long chains of molecules joined by hydrogen bonds — the relatively weak attractions between the positively charged region of one atom and the negatively charged region of the next.

“These dynamic bonds allow the material to self-heal,” said Chao Wang, another member of the research team. The molecules easily break apart, but then when they reconnect, the bonds reorganize themselves and restore the structure of the material after it gets damaged, he said. The result is a bendable material, which even at room temperature feels a bit like saltwater taffy left in the fridge.

To this resilient polymer, the researchers added tiny particles of nickel, which increased its mechanical strength. The nanoscale surfaces of the nickel particles are rough, which proved important in making the material conductive. Tee compared these surface features to “mini-machetes,” with each jutting edge concentrating an electrical field and making it easier for current to flow from one particle to the next.

The result was a polymer with uncommon characteristics. “Most plastics are good insulators, but this is an excellent conductor,” Bao said.

The next step was to see how well the material could restore both its mechanical strength and its electrical conductivity after damage.

The researchers took a thin strip of the material and cut it in half with a scalpel. After gently pressing the pieces together for a few seconds, the researchers found the material gained back 75 percent of its original strength and electrical conductivity. The material was restored close to 100 percent in about 30 minute, compared to days with human skin.

What’s more, the same sample could be cut repeatedly in the same place. After 50 cuts and repairs, a sample withstood bending and stretching just like the original.

The composite nature of the material created a new engineering challenge for the team. Bao and her co-authors found that although nickel was key to making the material strong and conductive, it also got in the way of the healing process by preventing the hydrogen bonds from reconnecting as well as they should.

For future generations of the material, Bao said, the team might adjust the size and shape of the nanoparticles, or even the chemical properties of the polymer, to get around this trade-off.

Nonetheless, Wang said the extent of these self-healing properties was truly surprising: “Before our work, it was very hard to imagine that this kind of flexible, conductive material could also be self-healing.”

Sensitive to the touch

The team also explored how to use the material as a sensor. Twisting or putting pressure on the synthetic skin changes the distance between the nickel particles and, therefore, the ease with which electrons can move. These subtle changes in electrical resistance can be translated into information about pressure and tension on the skin.

The material is sensitive enough to detect the pressure of a handshake. It might, therefore, be ideal for use in prosthetics.. The material is sensitive not only to downward pressure but also to flexing, so a prosthetic limb might someday be able to register the degree of bend in a joint.

Other uses include electrical devices and wires coated in this material, which could repair themselves and get electricity flowing again without costly and difficult maintenance, particularly in hard-to-reach places, such as inside building walls, vehicles, or aircraft.

The team’s goal to also to make the material stretchy and transparent, so that it might be suitable for wrapping and overlaying electronic devices or display screens.

The research was supported by the Air Force Office of Scientific Research.