‘Bubble pen’ can precisely write patterns with nanoparticles as small as 1 nanometer

January 15, 2016

Illustration of the bubble-pen pattern-writing process using an optically controlled microbubble on a plasmonic substrate. The small blue spheres are colloidal nanoparticles. (credit: Linhan Lin et al./Nano Letters)

Researchers in the Cockrell School of Engineering at The University of Texas at Austin have created “bubble-pen lithography” — a device and technique to quickly, gently, and precisely use microbubbles to “write” using gold, silicon and other nanoparticles between 1 and 100 nanometers in size as “ink” on a surface.

The new technology is aimed at allowing researchers to more easily build tiny machines, biomedical sensors, optical computers, solar panels, and other devices.

Existing lithography methods, which are used to etch or pattern materials on a substrate, are not capable of fixing nanoparticles to a specific location with precise and arbitrary control, and have optical-dimension limits. Those methods also require more resources and a clean-room environment.

Creating laser-controlled nanopatterns

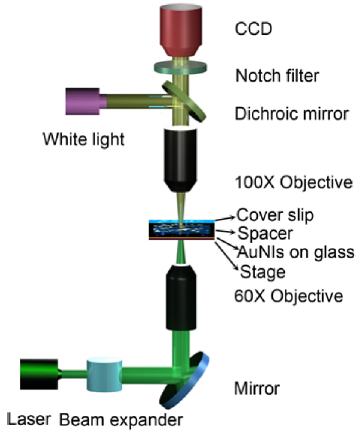

Experimental bubble-pen-lithography setup. A focused laser beam generates and positions a microbubble on a plasmonic substrate. A colloidal nanoparticle is dragged toward the microbubble, trapped on the bubble/water interface, and eventually immobilized on the substrate in the desired location. (credit: Linhan Lin et al./Nano Letters)

Using a design software program, bubble-pen lithography can deposit nanoparticles in real time in a pre-programmed pattern or design, similar to how 3-D printers work.

The researchers focus a laser to generate a hotspot that creates a microbubble out of vaporized water. The bubble attracts and captures a nanoparticle through a combination of gas pressure, thermal and surface tension, surface adhesion and convection.

The laser then steers the microbubble to move the nanoparticle on a site on the surface. When the laser is turned off, the microbubble disappears, leaving the particle on the surface. If necessary, the researchers can expand or reduce the size of the microbubble by increasing or decreasing the laser beam’s power.

The technique could be especially helpful for science and medicine because researchers would be able to precisely control cells, biological material, bacteria, or viruses for study and testing, said research team leader assistant professor Yuebing Zheng.

Other uses include testing prototypes and ideas for devices and materials more quickly, and eventually, large-scale, low-cost manufacturing of nanomaterials and devices.

Zheng is also planning to develop a portable version of the technique that works like a mobile phone for use in prototyping and disease diagnosis.

The researchers describe their patented device and technique in a paper published in the Jan. 13 issue of Nano Letters. The research received funding from the Beckman Young Investigator Award.

Cockrell School of Engineering | Engineers at the Cockrell School of Engineering show bubble-pen lithography in action, including generating a microbubble and depositing nanoparticles.

Abstract of Bubble-Pen Lithography

Current lithography techniques, which employ photon, electron, or ion beams to induce chemical or physical reactions for micro/nano-fabrication, have remained challenging in patterning chemically synthesized colloidal particles, which are emerging as building blocks for functional devices. Herein, we develop a new technique – bubble-pen lithography (BPL) – to pattern colloidal particles on substrates using optically controlled microbubbles. Briefly, a single laser beam generates a microbubble at the interface of colloidal suspension and a plasmonic substrate via plasmon-enhanced photothermal effects. The microbubble captures and immobilizes the colloidal particles on the substrate through coordinated actions of Marangoni convection, surface tension, gas pressure, and substrate adhesion. Through directing the laser beam to move the microbubble, we create arbitrary single-particle patterns and particle assemblies with different resolutions and architectures. Furthermore, we have applied BPL to pattern CdSe/ZnS quantum dots on plasmonic substrates and polystyrene (PS) microparticles on two-dimensional (2D) atomic-layer materials. With the low-power operation, arbitrary patterning and applicability to general colloidal particles, BPL will find a wide range of applications in microelectronics, nanophotonics, and nanomedicine.