Crafting color coatings from nanometer-thick layers of gold and germanium

December 24, 2014

In 2012, a Harvard research team demonstrated interference effects in nanometer-thick layers of gold and germanium deposited on silicon to achieve different colors, pictured here. Their latest work takes it much further, demonstrating that the same effects can be achieved on rough surfaces. (Credit: Mikhail Kats, Romain Blanchard, and Patrice Genevet.)

Harvard scientists who developed a technique in 2012 that coats a gray metallic object with a semiconductor layer just a few nanometers thick to achieve a variety of vibrant hues have now applied the technique to almost any rough or flexible material, from wearable fabrics to stretchable electronics.

The coating exploits optical interference effects in the thin films. Researcher Mikhail Kats compares it to the iridescent rainbows that are visible when oil floats on water. Carefully tuned in the laboratory, these coatings can produce a bright, solid pink — or, say, a vivid blue — using the same two metals, applied with only a few atoms’ difference in thickness.

It was not obvious that the same color effects would be visible on rough substrates, because interference effects are usually highly sensitive to the angle of light. And on a sheet of paper, Kats explains, “There are hills and valleys and fibers and little things sticking out—that’s why you can’t see your reflection in it. The light scatters.”

Colors based on coating thickness

On the other hand, the applied films are so extremely thin that they interact with light almost instantaneously, so looking at the coating straight on or from the side—or, as it turns out, looking at those rough imperfections in the paper—doesn’t make much difference to the color. And the paper remains flexible, as usual.

Demonstrating the technique in the cleanroom at the Center for Nanoscale Systems, Mikhail Kats uses an electron-beam evaporator to apply the gold and germanium coating. He seals the paper sample inside the machine’s chamber, and a pump sucks out the air until the pressure drops to a staggering 10-6 Torr (a billionth of an atmosphere). A stream of electrons strikes a piece of gold held in a carbon crucible, and the metal vaporizes, traveling upward through the vacuum until it hits the paper. Repeating the process, Kats adds the second layer. A little more or a little less germanium makes the difference between indigo and crimson. (Credit: Eliza Grinnell, Harvard SEAS)

This particular lab technique, Kats points out, is unidirectional, so to the naked eye very subtle differences in the color are visible at different angles, where slightly less of the metal has landed on the sides of the paper’s ridges and valleys.

“You can imagine decorative applications where you might want something that has a little bit of this pearlescent look, where you look from different angles and see a different shade,” he notes.

“But if we were to go next door and use a reactive sputterer instead of this e-beam evaporator, we could easily get a coating that conforms to the surface, and you wouldn’t see any differences.”

Many different pairings of metal are possible, too. “Germanium’s cheap. Gold is more expensive, of course, but in practice we’re not using much of it,” Kats explains. Capasso’s team has also demonstrated the technique using aluminum.

“This is a way of coloring something with a very thin layer of material, so in principle, if it’s a metal to begin with, you can just use 10 nanometers to color it, and if it’s not, you can deposit a metal that’s 30 nm thick and then another 10 nm. That’s a lot thinner than a conventional paint coating that might be between a micron and 10 microns thick.”

In those occasional situations where the weight of the paint matters, this could be very significant. The external fuel tank of NASA’s space shuttle used to be painted white. After the first two missions, engineers stopped painting it and saved 600 pounds of weight.

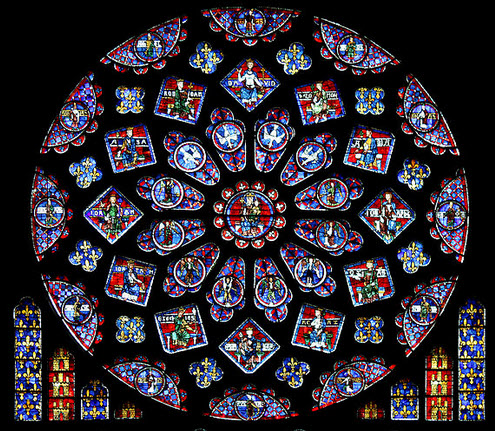

Using a different nanotechnological effect involving resonant plasmonics, medieval artisans created colored stained-glass windows in churches by incorporating nanoparticles of different materials and different sizes while making the glass from sand. For instance, ruby glass was created by adding gold chloride, while uranium glass, which glows in the dark, was created by adding uranium oxide, according to “Nanoparticle Stained Glass,” a University of Wisconsin-Madison tutorial document. Shown here, the north transept rose of Chartres Cathedral in France. Each of the miniature tableaux expands into a full-size tableau. (Credit: Eusebius/Wikimedia Commons).

Uses in optoelectronic devices

Because the metal coatings absorb a lot of light, reflecting only a narrow set of wavelengths, Federico Capasso, the Robert L. Wallace Professor of Applied Physics and Vinton Hayes Senior Research Fellow in Electrical Engineering, suggests that they could also be incorporated into optoelectronic devices like photodetectors and solar cells.

“The fact that these can be deposited on flexible substrates has implications for flexible and maybe even stretchable optoelectronics that could be part of your clothing or could be rolled up or folded,” Capasso says.

Harvard’s Office of Technology Development continues to pursue commercial opportunities for the new color coating technology and welcomes contact from interested parties.

Kats, who concludes his year-long postdoctoral research position at SEAS this month, will become an assistant professor at the University of Wisconsin, Madison, in January. He credits those many hours spent in Harvard’s state-of-the-art laboratory facilities for much of his success in applied physics.

“You learn so much while you’re doing it,” Kats says. “You can be creative, discover something along the way, apply something new to your research. It’s marvelous that we have students and postdocs down here making things.”

The Capasso group research was published in the journal Applied Physics Letters and supported by the Air Force Office of Scientific Research and Draper Laboratory. The Center for Nanoscale Systems is a member of the National Nanotechnology Infrastructure Network, supported by the National Science Foundation.

Abstract of Ultra-thin optical interference coatings on rough and flexible substrates

Recently demonstrated ultra-thin optical coatings comprising nanometer-thick highly absorbing films on top of reflecting substrates can display strong optical interference effects, resulting in structural colors and absorption enhancement. Here, we demonstrate that these optical interference effects persist when the films are deposited on substrates that have a large degree of roughness and inhomogeneity on micro- and nano-scales. In particular, we deposited films of gold and amorphous germanium onto paper which serves as a rough and flexible substrate and observe matte interference colors that vary as a function of the germanium thickness.