Disney Research-CMU design tool helps novices design 3-D-printable robotic creatures

November 9, 2015

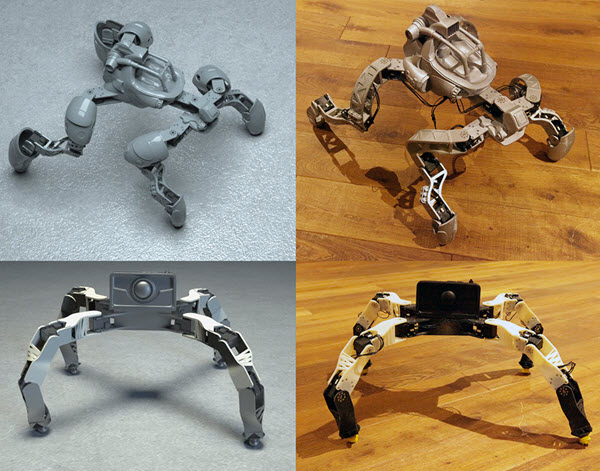

Digital designs for robotic creatures are shown on the left and the physical prototypes produced via 3-D printing are on the right (credit: Disney Research, Carnegie Melon University)

Now you can design and build your own customized walking robot using a 3-D printer and off-the-shelf servo motors, with the help of a new DYI design tool developed by Disney Research and Carnegie Mellon University.

You can specify the shape, size, and number of legs for your robotic creature, using intuitive editing tools to interactively explore design alternatives. The system takes over much of the non-intuitive and tedious task of planning the motion of the robot, and ensures that your design is capable of moving the way you want and not fall down. Or you can alter your creature’s gait as desired.

Six robotic creatures designed with the Disney Research-CMU interactive design system: one biped, four quadrupeds and one five-legged robot (credit: Disney Research, Carnegie Melon University)

“Progress in rapid manufacturing technology is making it easier and easier to build customized robots, but designing a functioning robot remains a difficult challenge that requires an experienced engineer,” said Markus Gross, vice president of research for Disney Research. “Our new design system can bridge this gap and should be of great interest to technology enthusiasts and the maker community at large.”

The research team presented the system at SIGGRAPH Asia 2015, the ACM Conference on Computer Graphics and Interactive Techniques, in Kobe, Japan.

Design viewports

The design interface features two viewports: one that lets you edit the robot’s structure and motion and a second that displays how those changes would likely alter the robot’s behavior.

You can load an initial, skeletal description of the robot and the system then creates an initial geometry and places a motor at each joint position. You can then edit the robot’s structure, adding or removing motors, or adjust their position and orientation.

The researchers have developed an efficient optimization method that uses an approximate dynamics model to generate stable walking motions for robots with varying numbers of legs. In contrast to conventional methods that can require several minutes of computation time to generate motions, the process takes just a few seconds, enhancing the interactive nature of the design tool.

3-D printer-ready designs

Once the design process is complete, the system automatically generates 3-D geometry for all body parts, including connectors for the motors, which can then be sent to a 3-D printer for fabrication.

In a test of creating two four-legged robots, it took only minutes to design these creatures, but hours to assemble them and days to produce parts on 3-D printers,” said Bernhard Thomaszewski, a research scientist at Disney Research. “It is both expensive and time-consuming to build a prototype — which underscores the importance of a design system [that] produces a final design without the need for building multiple physical iterations.”

The research team also included roboticists at ETH Zurich. For more information, see Interactive Design of 3D-Printable Robotic Creatures (open access) and visit the project website.

Disney Research | Interactive Design of 3D Printable Robotic Creatures