Graphene rubber bands: flexible, low-cost body sensors

August 21, 2014

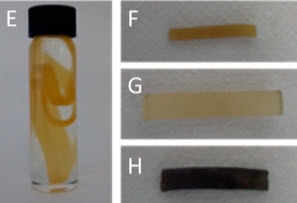

(E) Rubber band soaking in toluene. (F) An untreated rubber band. (G) a band section after soaking in toluene for 3.5 hours. (H) A graphene-infused band prepared by swelling in toluene then soaking in an N-methyl-pyrrolidone-water-graphene mixture for 4 hours followed by washing and drying. (Credit: Conor S. Boland et al./ACS NANO)

Q: What do you get when you add graphene to a rubber band?

A: A flexible sensor sensitive enough for medical use that can be made cheaply.

So say researchers from the University of Surrey and Trinity College Dublin, who have done just that.

Once treated, the rubber bands remain highly pliable, the researchers report, and graphene can be used as a sensor to measure a patient’s breathing, heart rate, or movement, alerting doctors to any irregularities,

Although body motion sensors already exist in different forms, they have not been widely used because of their complexity and cost of production.

The researchers, Alan Dalton from the University of Surrey and Jonathan Coleman from Trinity College, suggest that the graphene-infused rubber bands (or “G-bands”) could change all that and “revolutionize remote healthcare.”

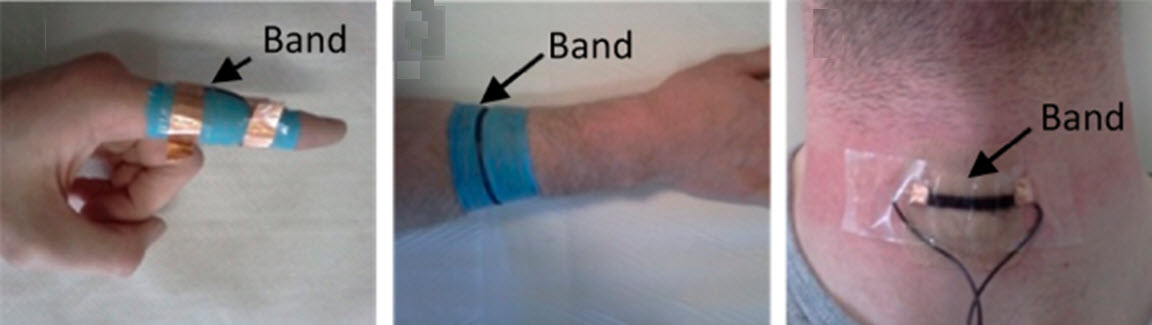

G-bands could sense motion such as breathing, pulse and joint movement, and could be used to create lightweight sensor suits for vulnerable patients such as premature babies, making it possible to remotely monitor their subtle movements and alert a doctor to any worrying behaviors.

Applications of G-bands as body monitors (left to right: finger, wrist, throat) (credit: Conor S. Boland et al./ACS NANO)

The researchers also say the G-band sensors are “extraordinarily cheap” compared to existing technologies. “Each device would probably cost pennies instead of pounds, making it ideal technology for use in developing countries where there are not enough medically trained staff to effectively monitor and treat patients quickly,” said Coleman.

Abstract of ACS Nano paper

Monitoring of human bodily motion requires wearable sensors that can detect position, velocity and acceleration. They should be cheap, lightweight, mechanically compliant and display reasonable sensitivity at high strains and strain rates. No reported material has simultaneously demonstrated all the above requirements. Here we describe a simple method to infuse liquid-exfoliated graphene into natural rubber to create conducting composites. These materials are excellent strain sensors displaying 104-fold increases in resistance and working at strains exceeding 800%. The sensitivity is reasonably high, with gauge factors of up to 35 observed. More importantly, these sensors can effectively track dynamic strain, working well at vibration frequencies of at least 160 Hz. At 60 Hz, we could monitor strains of at least 6% at strain rates exceeding 6000%/s. We have used these composites as bodily motion sensors, effectively monitoring joint and muscle motion as well and breathing and pulse.