Improved artificial blood vessels

February 3, 2015

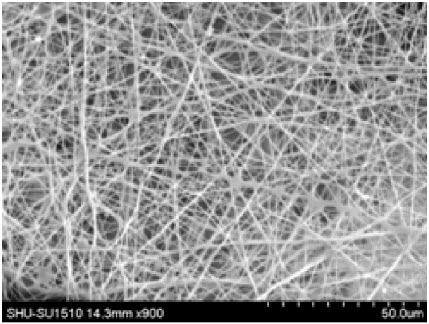

SEM micrograph of chitosan-PVA nanofibers in three-layered composite graft (credit: Yuanyuan Liu et al./AIP Advances)

By combining micro-imprinting and electro-spinning techniques, researchers at Shanghai University’s Rapid Manufacturing Engineering Center have developed a vascular graft (blood-vessel bypass) composed of three layers for the first time.

This tri-layered composite allowed researchers to combine separate materials to provide mechanical strength and also promote new cell growth, not possible with existing vascular grafts, which are limited to a single or double layer.

Vascular grafts are surgically attached to an obstructed or otherwise unhealthy blood vessel to permanently redirect blood flow, such as in coronary bypass surgery. Traditional grafts work by repurposing existing vessels from the patient’s own body or from a suitable donor.

However, these sources are often insufficient because of the limited supply in a patient’s body, and may be afflicted by the same underlying conditions that necessitate the graft in the first place. So there has been a great deal of research towards developing synthetic vessels that can mimic natural ones, allowing new cells to grow around them and then degrade away, thereby creating new vessels.

Tissue engineering vascular graft can be used for treating stenotic vessels (credit: Yuanyuan Liu/Shanghai University)

“The composite vascular grafts could be better candidates for blood vessel repair,” said Yuanyuan Liu, an associate professor at the Rapid Manufacturing Engineering Center.

Liu’s team had previously worked with bone scaffolds, which are used to repair bone defects, before turning their attention to cardiovascular disease, and thus vascular grafts.

They describe their current research in the journal AIP Advances.

As a rule, surrogate scaffolds need to mimic the natural vasculature of their targeted tissue as much as possible. For blood vessel surrogates, this structural mimicry can be fabricated by electrospinning, a process that uses an electrical charge to draw liquid inputs — here a mixture of chitosan and polyvinyl alcohol — into incredibly fine fibers.

Electrospinning also allows for a high surface-to-volume ratio of nanofibers, providing ample space for host cells to grow and connect. These components all naturally degrade within six months to a year, leaving behind a new, intact blood vessel.

The resulting structure, however, isn’t very rigid. So the researchers designed a three-layer model, in which the mixture was electrospun onto both sides of a microimprinted middle layer of poly-p-dioxanone, a biodegradable polymer commonly used in biomedical applications. The ends of this sheet were then folded and attached to make a tube-like vessel.

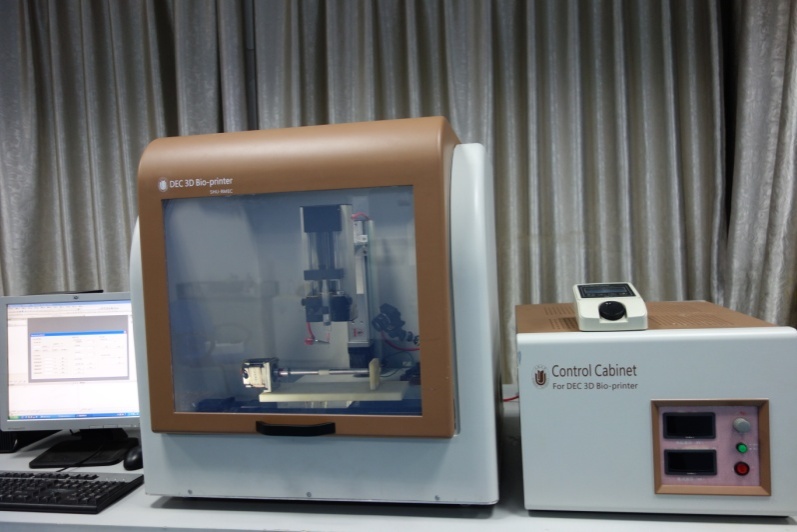

The researchers use 3D bio-printer to prepare a variety of scaffolds for tissue defect repair (credit: Yuanyuan Liu/Shanghai University)

Liu and her team then seeded the scaffold with rat fibroblast cells, which are ideal candidates because of their ease of cultivation and quick growth rate, to test the scaffold’s efficacy in promoting cellular expansion and integration.

The researchers found that the cells on these composite scaffolds proliferated quickly, likely due to the functional amino and hydroxyl groups introduced by the chitosan.

While a good deal of work remains before the prospect of human trials, Liu and her group are optimistic about the future of their research. Their next project is to test the implants in an animal model, to observe the structure’s efficacy with live vascular cells.

Abstract for Composite vascular repair grafts via micro-imprinting and electrospinning

Composite vascular grafts formed by micro-imprinting and electrospinning exhibited improvedmechanical properties relative to those formed by electrospinning alone. The three-layeredcomposite grafts mimic the three-layered structure of natural blood vessels. The middle layer is made by micro-imprinting poly-p-dioxanone (PPDO), while the inner and outer layers areelectrospun mixtures of chitosan and polyvinyl alcohol. The graft morphology is characterized with scanning electron microscopy. For constant graft thicknesses, the PPDO increases the mechanical strength. Cells cultivated on the vascular grafts adhere and proliferate better because of the natural, biological chitosan in the inner and outer layers. Overall, the compositescaffolds could be good candidates for blood vessel repair.