Low-cost 2D-printed ‘paper electronics’

November 21, 2014

Paper-baaed touch pad on curved surface (credit: (credit: American Chemical Society)

An international team of scientists has developed a fast, low-cost way of making low-cost medical electronic touch sensors by printing conductive silver nanowire inks directly on paper, using a 2D programmed printing machine.

Anming Hu of the University of Tennessee Department of Mechanical, Aerospace and Biomedical Engineering and colleagues point out that paper, which is available worldwide at low cost, makes an excellent surface for lightweight, foldable “paper electronics: that could be made and used nearly anywhere.

Scientists have already fabricated point-of-care diagnostic tests and portable DNA detectors using paper. But these require complicated and expensive lithography manufacturing techniques.

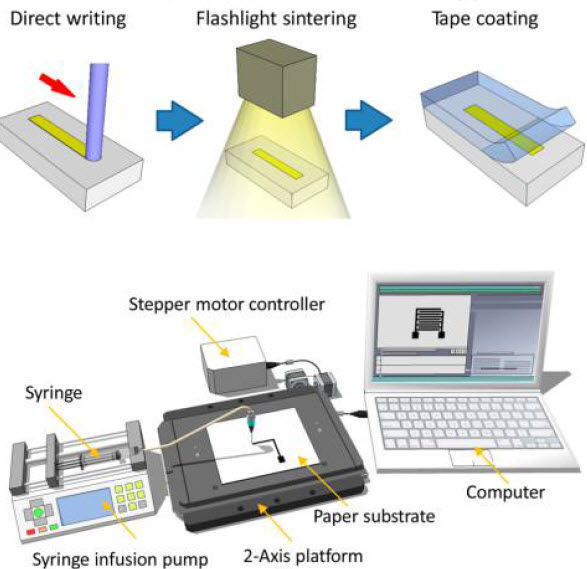

Silver nanowire ink, which is highly conductive and stable, offers a more practical solution, Hu says. His team developed a system for printing a pattern of silver ink on paper within a few minutes and then sintering (hardening) it with the light of a camera flash.

The resulting capacitive touch device was ultrathin and ultralight and responded to touch even when curved, folded, and unfolded 15 times, and rolled and unrolled 5,000 times. It could serve as the basis for many useful applications, the researchers suggest.

Process and equipment for printing prototype paper-based touch pad (credit: American Chemical Society)

The study was published in the journal ACS Applied Materials & Interfaces.

Abstract of Direct Writing on Paper of Foldable Capacitive Touch Pads with Silver Nanowire Inks

Paper-based capacitive touch pads can be fabricated utilizing high-concentration silver nanowire inks needle-printed directly onto paper substrates through a 2D programmable platform. Post deposition, silver nanowire tracks can be photonically sintered using a camera flash to reduce sheet resistance similar to thermal sintering approaches. Touch pad sensors on a variety of paper substrates can be achieved with optimized silver nanowire tracks. Rolling and folding trials, which yielded only modest changes in capacitance and no loss of function, coupled with touch pad functionality on curved surfaces, suggest sufficient flexibility and durability for paper substrate touch pads to be used in diverse applications. A simplified model to predict touch pad capacitance variation ranges with differing touch conditions was developed, with good agreement against experimental results. Such paper-based touch pads have the advantage of simple structure, easy fabrication, and fast sintering, which holds promise for numerous commercial applications including low-cost portable devices where ultrathin and lightweight features, coupled with reliable bending stability are desirable.