New method 3D-prints fully functional electronic circuits

November 10, 2017

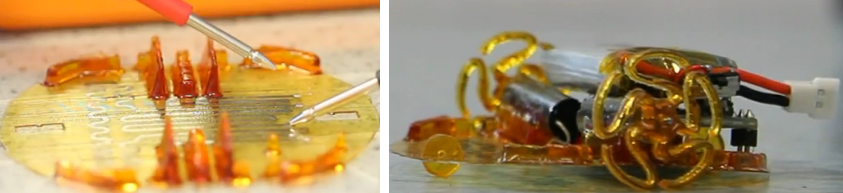

(Left) Conductive and polymeric inks were simultaneously inkjet-printed and solidified in a single process using UV irradiation. (Right) Microcontroller, batteries, and motors were then manually embedded in the system, creating a functioning miniature car. (credit: Ehab Saleh et al./University of Nottingham)

Researchers at the University of Nottingham have developed a method for rapidly 3D-printing fully functional electronic circuits such as antennas, medical devices, and solar-energy-collecting structures.

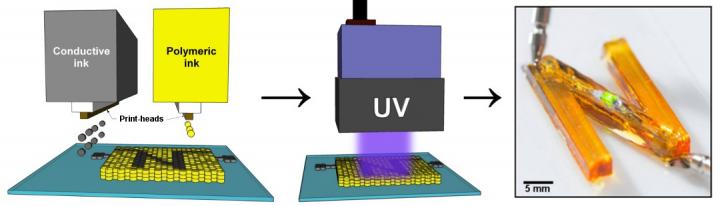

Unlike conventional 3D printers, these circuits can contain both both electrically conductive metallic inks (like the silver wires in the photo above) and insulating polymeric inks (like the yellow and orange support structure). A UV light is used rapidly solidify the inks).

The “multifunctional additive manufacturing” (MFAM) method combines 3D printing, which is based on layer-by-layer deposition of materials to create 3D devices, with 2D-printed electronics. It prints both conductors and insulators in a single step, expanding the range of functions in electronics (but not integrated circuits and other complex devices).

A schematic diagram showing how UV irradiation heats and solidifies conductive and dielectric inks to form the letter N and silver tracks that connect a green LED to a power source. (credit: University of Nottingham)

The researchers discovered that silver nanoparticles in conductive inks are capable of absorbing UV light efficiently. The absorbed UV energy is converted into heat, which evaporates the solvents of the conductive ink and fuses the silver nanoparticles. This process affects only the conductive ink so it doesn’t damage any adjacent printed polymers.

For example, the method could create wristband that includes a pressure sensor, wireless communication circuitry, and capacitor (functioning as a battery), customized for the wearer — all in a single process.

The new method overcomes some of the challenges in manufacturing fully functional devices that contain plastic and metal components in complex structures, where different methods are required to solidify each material. The method speeds up the solidification process of the conductive inks to less than a minute per layer. Previously, this process took much longer to be completed using conventional heat sources such as ovens and hot plates, making it impractical when hundreds of layers are needed to form an object.

Abstract of 3D Inkjet Printing of Electronics Using UV Conversion

The production of electronic circuits and devices is limited by current manufacturing methods that limit both the form and potentially the performance of these systems. Additive manufacturing (AM) is a technology that has been shown to provide cross-sectoral manufacturing industries with significant geometrical freedom. A research domain known as multifunctional AM (MFAM) in its infancy looks to couple the positive attributes of AM with application in the electronics sector can have a significant impact on the development of new products; however, there are significant hurdles to overcome. This paper reports on the single step MFAM of 3D electronic circuitry within a polymeric structure using a combination of conductive and nonconductive materials within a single material jetting-based AM system. The basis of this breakthrough is a study of the optical absorption regions of a silver nanoparticle (AgNP) conductive ink which leads to a novel method to rapidly process and sinter AgNP inks in ambient conditions using simple UV radiation contemporaneously with UV-curing of deposited polymeric structures.