First large-scale graphene fabrication

May 15, 2015

Fabrication size limits — one of the barriers to using graphene on a commercial scale — could be overcome using a new method developed by researchers at the Department of Energy’s Oak Ridge National Laboratory (ORNL).

Graphene, a one-atom-thick material that is about 100 times stronger than steel by weight, has enormous commercial potential but has been impractical to employ on a large scale, mainly because of size limits and expense.

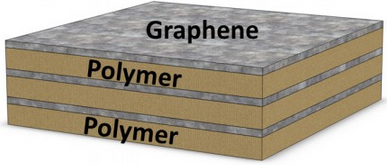

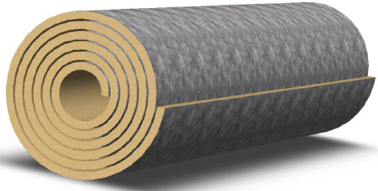

Now, using chemical vapor deposition, a team led by ORNL’s Ivan Vlassiouk has fabricated polymer laminate (layered) composites containing 2-inch-by-2-inch graphene sheets created from large continuous sheets of single-layer graphene. They were also able to produce graphene-based fibers.

Outperforming current composite materials

Graphene-polymer fiber (credit: ORNL)

The new process eliminates flake dispersion and agglomeration (sticking together) problems. The process has potential to outperform current state of the art composite materials in both mechanical properties and electrical conductivity.

The process also uses 50 times less actual graphene in the polymer, compared to current state-of-the-art samples — a key to making the material competitive in the market, Vlassiouk said.

If the ORNL team can reduce cost and demonstrate scalability, graphene could be used in aerospace (structural monitoring, flame-retardants, anti-icing, conductive), the automotive sector (catalysts, wear-resistant coatings), structural applications (self-cleaning coatings, temperature control materials), electronics (displays, flexible printed electronics, thermal management), energy (photovoltaics, filtration, energy storage) and manufacturing (catalysts, barrier coatings, filtration).

The findings are reported in the journal Applied Materials & Interfaces. Scientists at New Mexico State University were also involved in the research, which was supported by ORNL’s Laboratory Directed Research and Development program.

Abstract of Strong and Electrically Conductive Graphene-Based Composite Fibers and Laminates

Graphene is an ideal candidate for lightweight, high-strength composite materials given its superior mechanical properties (specific strength of 130 GPa and stiffness of 1 TPa). To date, easily scalable graphene-like materials in a form of separated flakes (exfoliated graphene, graphene oxide, and reduced graphene oxide) have been investigated as candidates for large-scale applications such as material reinforcement. These graphene-like materials do not fully exhibit all the capabilities of graphene in composite materials. In the current study, we show that macro (2 inch × 2 inch) graphene laminates and fibers can be produced using large continuous sheets of single-layer graphene grown by chemical vapor deposition. The resulting composite structures have potential to outperform the current state-of-the-art composite materials in both mechanical properties and electrical conductivities (>8 S/cm with only 0.13% volumetric graphene loading and 5 × 103 S/cm for pure graphene fibers) with estimated graphene contributions of >10 GPa in strength and 1 TPa in stiffness.