Super-resolution atom-by-atom laser machining method allows for making nanoscale devices

March 11, 2014

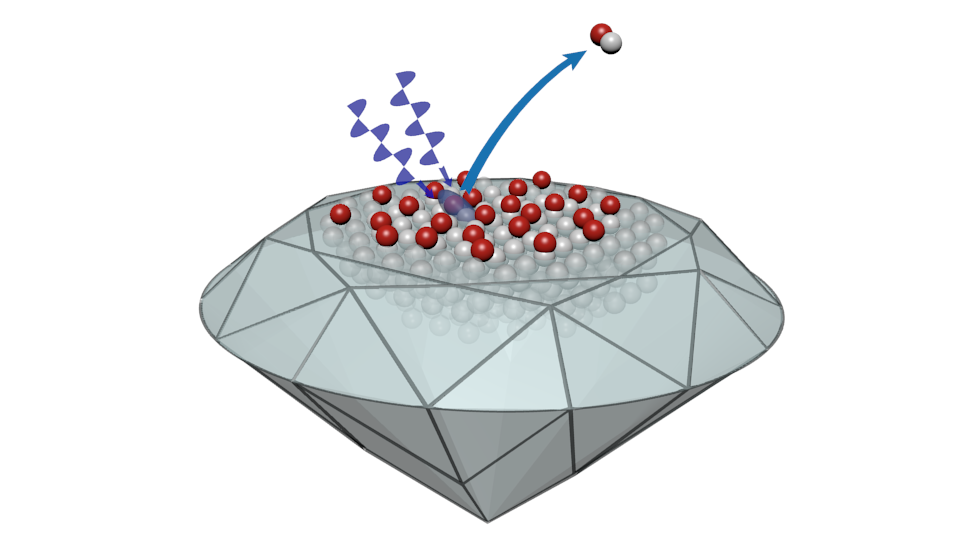

Researchers have discovered that it is possible to remove atoms from a surface using ultraviolet lasers and confining the interaction to the atomic scale (credit: Chris Baldwin)

Australian researchers have discovered how to use laser light to pick apart a substance atom by atom, allowing for creating new nanoscale diamond devices.

“Lasers are known to be very precise at cutting and drilling materials on a small scale — less than the width of a human hair, in fact — but on the atomic scale they have notoriously poor resolution,” says lead researcher Associate Professor Richard Mildren.

“If we can harness lasers at higher resolutions, the opportunities at the atomic level are tremendous, especially for future nanoscale devices in high-density data storage, quantum computers, nano-sensors and high-power on-chip lasers.”

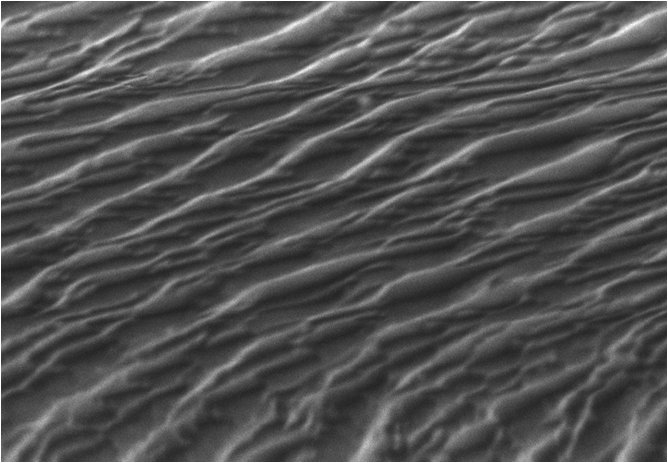

Electron microscope of an emergent nano-pattern etched into the diamond surface (credit Rich Mildren)

Through their research, Mildren and Macquarie University colleagues Andrew Lehmann and Carlo Bradac have now discovered that it is possible to remove atoms from a surface at atomic scale, using ultraviolet lasers.

The phenomenon avoids the heat generation problem with using lasers that has previously restricted the ability to make very small precise cuts. It also enables targeted bond breakage and atom manipulation for covalently bonded and other materials that are incompatible with scanning probe microscopy methods.

“So far we have used the technique to demonstrate structures in diamond of size about 20 nanometers, which is the size of large molecules,” says Mildren.

“However, the technique looks highly promising for doing much better, enabling manipulation of surfaces with the ultimate single atom precision, or more than a ten thousand times smaller than that possible by standard laser machining techniques.”

The research was published March 4 in Nature Communications.

Abstract of Nature Communications paper

Optical techniques have advanced considerably in recent years to enable processing of surfaces with a resolution less than the wavelength of light. Despite the highly selective nature of light-matter interactions, however, efforts to increase resolution to the scale of single atoms are hampered by rapid and efficient dissipation of the absorbed energy to the surrounding matrix. Here we show that two-photon surface excitation using ultraviolet light provides a method for selectively removing carbon from diamond surfaces. Polished surfaces etched by this method develop ultra-deep subwavelength structures with morphologies dependent on the polarization of the incident laser with respect to the crystal axes. As well as revealing a practical and versatile method for nano-patterning of diamond surfaces, we show that the results comprise mesoscopic evidence for bond scission via a highly localized optical interaction that may lead to the development of new optical approaches for ultra-nanoscale (<10 nm) surface structuring.