These are the thinnest, strongest plates that can be picked up by hand

December 4, 2015

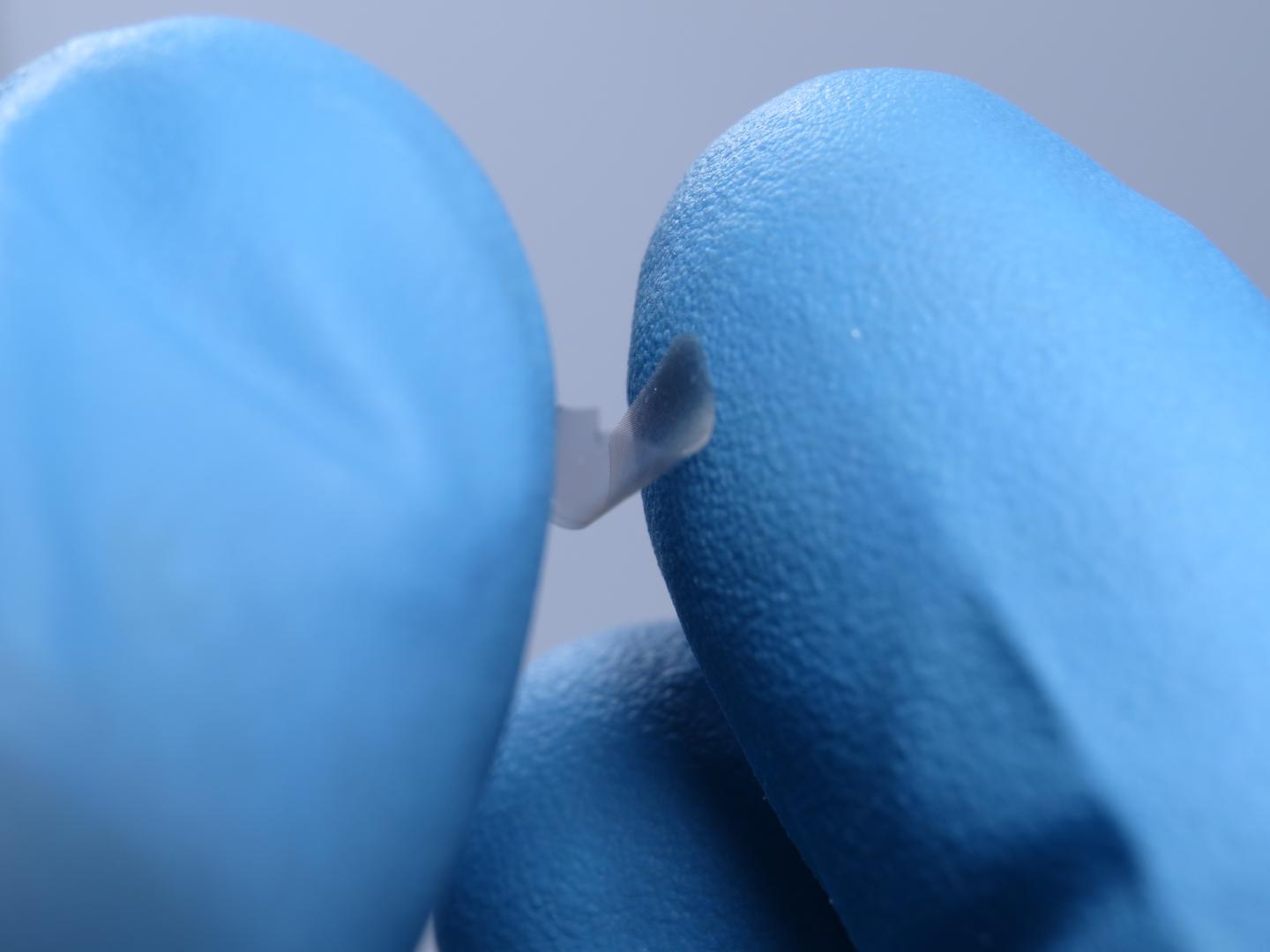

Even though they are less than 100 nanometers thick, the researchers’ plates are strong enough to be picked up by hand and retain their shape after being bent and squeezed. (credit: University of Pennsylvania)

Researchers at the University of Pennsylvania have created the thinnest plates that can be picked up and manipulated by hand, using corrugated plates of aluminum oxide. They are thousands of times thinner than a sheet of paper and hundreds of times thinner than household cling wrap, but they spring back to their original shape after being bent and twisted.

Like cling wrap, comparably thin materials immediately curl up on themselves and get stuck in deformed shapes if they are not stretched on a frame or backed by another material. Graphene is even thinner, but it also curls up.

Being able to stay in shape without additional support would allow this material, and others designed on its principles, to be used in aviation and other structural applications where low weight is at a premium.

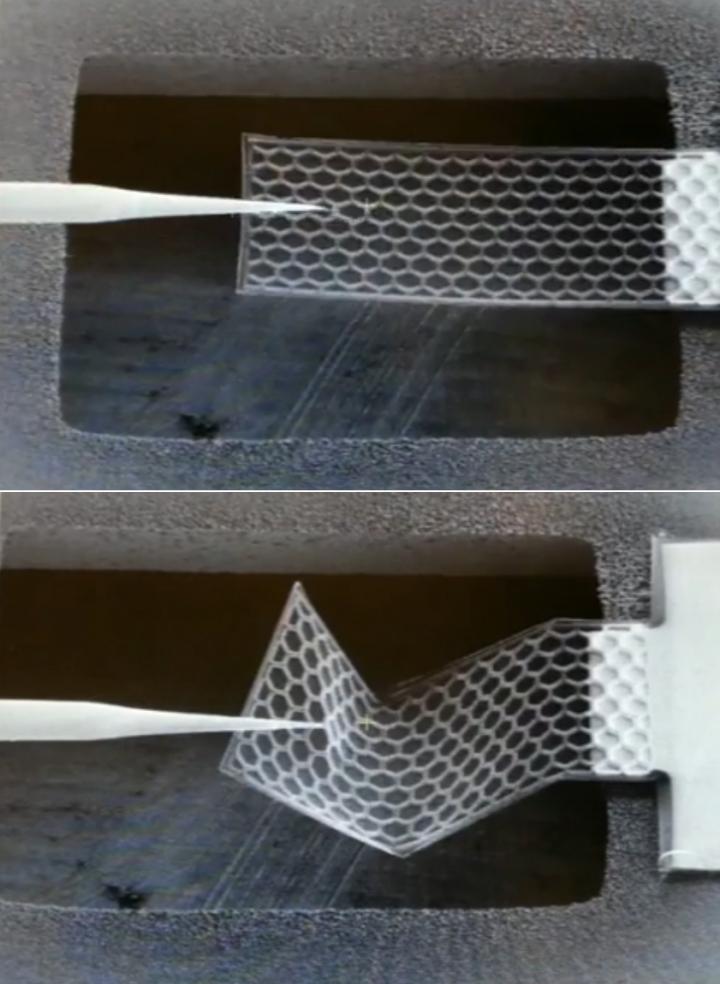

The plates’ corrugation allow them to remain stiff and stable without the addition of a heavy frame or backing. (credit: University of Pennsylvania)

Mechanical metamaterials

The innovation was to use corrugation (like corrugated cardboard) instead of a frame to keep the material rigid and freestanding. The researchers’ plates are between 25 and 100 nanometers thick and are made of aluminum oxide, which is deposited one atomic layer at a time to achieve precise control of thickness and their distinctive honeycomb shape.

“Aluminum oxide is actually a ceramic, so something that is ordinarily pretty brittle,” said Igor Bargatin, Assistant Professor of Mechanical Engineering and Applied Mechanics. “You would expect it, from daily experience, to crack very easily. But the plates bend, twist, deform and recover their shape in such a way that you would think they are made out of plastic. The first time we saw it, I could hardly believe it.”

The hexagonal corrugation of the plates is responsible for their stiffness and strength. (credit: University of Pennsylvania)

The plates’ corrugation provides enhanced stiffness. When held from one end, similarly thin films would readily bend or sag, while the honeycomb plates remain rigid. This guards against the common flaw in un-patterned thin films, where they curl up on themselves.

This ease of deformation is tied to another behavior that makes ultra-thin films hard to use outside controlled conditions: they have the tendency to conform to the shape of any surface and stick to it due to Van der Waals forces. Once stuck, they are hard to remove without damaging them. Totally flat films are also particularly susceptible to tears or cracks, which can quickly propagate across the entire material.

The corrugated pattern of the plates is an example of a relatively new field of research: mechanical metamaterials. Like their electromagnetic counterparts, mechanical metamaterials achieve otherwise impossible properties from the careful arrangement of nanoscale features. With mechanical metamaterials, these properties are things like stiffness and strength, rather than their ability to manipulate electromagnetic waves.

A Solara 50 solar-powered drone by Google-owned Titan Aerospace (credit: Titan Aerospace)

That combination of traits could be used to make wings for insect-inspired flying robots or solar-powered drones for beaming the Internet down to Earth that are being explored by Google and Facebook.

“The wings of insects are a few microns thick, and can’t thinner because they’re made of cells,” Bargatin said. “The thinnest man-made wing material I know of is made by depositing a Mylar film on a frame, and it’s about half a micron thick. Our plates can be ten or more times thinner than that, and don’t need a frame at all. As a result, they weigh as little as than a tenth of a gram per square meter.”

The research was published in an open-access paper in the journal Nature Communications.

Abstract of Ultralight shape-recovering plate mechanical metamaterials

Unusual mechanical properties of mechanical metamaterials are determined by their carefully designed and tightly controlled geometry at the macro- or nanoscale. We introduce a class of nanoscale mechanical metamaterials created by forming continuous corrugated plates out of ultrathin films. Using a periodic three-dimensional architecture characteristic of mechanical metamaterials, we fabricate free-standing plates up to 2 cm in size out of aluminium oxide films as thin as 25 nm. The plates are formed by atomic layer deposition of ultrathin alumina films on a lithographically patterned silicon wafer, followed by complete removal of the silicon substrate. Unlike unpatterned ultrathin films, which tend to warp or even roll up because of residual stress gradients, our plate metamaterials can be engineered to be extremely flat. They weigh as little as 0.1 g cm−2 and have the ability to ‘pop-back’ to their original shape without damage even after undergoing multiple sharp bends of more than 90°.