Unexpected adhesion properties of graphene may lead to new nanotechnology devices

August 29, 2011

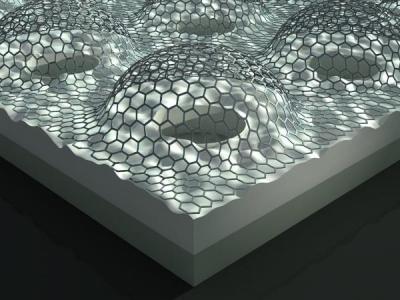

Pressurized graphene membranes could lead to new graphene-based mechanical devices (credit: Victor Tzen and Rex Tzen)

Graphene has surprisingly powerful adhesion qualities that could make possible graphene-based mechanical devices such as gas separation membranes, researchers at the University of Colorado Boulder have found.

The team measured the adhesion energy of graphene sheets, ranging from one to five atomic layers, with a glass substrate, using a pressurized “blister test” to quantify the adhesion between graphene and glass plates. The adhesion energies were several orders of magnitude larger than those in typical micromechanical structures.

“A gas separation membranes is a porous membrane that acts as a filter to separate gases,” said professor Scott Bunch. “Adhesion in this case is important because the maximum pressure difference you apply across the membrane will depend on how strongly the graphene is adhered to the surface it is supported on. At too high a pressure difference, the membrane will separate from the surface.

The researchers provided the first experimental measurements of the adhesion of graphene nanostructures, showing that van der Waals forces — the sum of the attractive or repulsive forces between molecules — clamp the graphene samples to the substrates and also hold together the individual graphene sheets in multilayer samples.

Their experiments also showed that the extreme flexibility of graphene allows it to conform to the topography of even the smoothest substrates, the researchers said.

Ref.: Steven P. Koenig, et al., Ultrastrong adhesion of graphene membranes, Nature Nanotechnology, 2011; [DOI:10.1038/nnano.2011.123]